Popular Science This article will help you understand the difference between COB and full flip-chip

As an important product technology trend under the development of LED display micro-pitch, the innovation and market share of Mini & Micro LED products using COB packaging technology are rapidly expanding in recent years. Since 2023, COB has begun to replace the SMD market, and this trend has become more obvious since 2024. According to incomplete statistics, COB has occupied nearly 70% of the market share in P1.2 dot pitch, and has gradually become a new growth point in the development of the LED market. Although COB technology is so popular, there are still many end customers and consumers who are still ambiguous about what is COB and what is full flip-chip, and they can’t tell the difference.

What is COB technology?

COB stands for Chip on Board, which is the chip on board packaging technology, as opposed to the traditional SMD (Surface Mounted Devices) or surface mount packaging device technology.

SMD technology requires the packaging factory to first package the RGB (red, green and blue) three-color LED chips into lamp beads, and then the module factory will mount the lamp beads on the PCB board through SMT to make LED display modules (see the figure below).

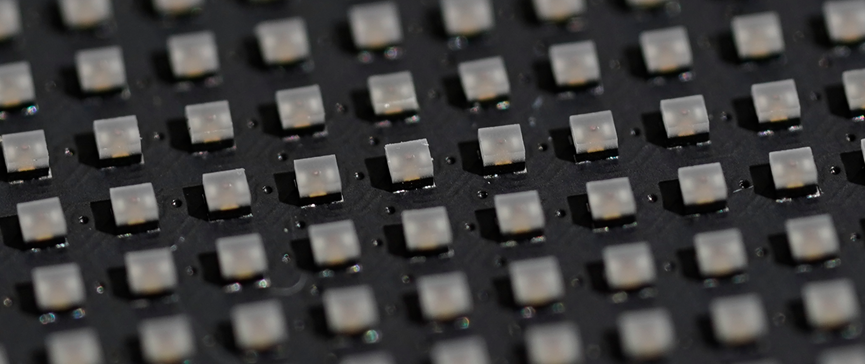

COB technology directly bonds the LED chip to the PCB board, and then packages it into an integrated LED display module (see the figure below). This packaging method has huge advantages in production efficiency, imaging quality, protection, and small micro-pitch applications.

What is full flip-chip?

In the COB technology camp, according to the different LED chips used, it is divided into regular COB, mixed COB and full flip COB.

1. Regular COB

Its advantage lies in cost. Formal chips came out earlier than flip chips, are more widely used, have more mature and stable processes, and are cheaper. However, formal COB also has many defects. Formal chips must be bonded with wires, and this process greatly increases the instability of the product. First, wire bonding is prone to metal migration problems under humid conditions, leading to dead lights, caterpillars and other problems, reducing the yield of the product; secondly, the positive electrode greatly affects the light output efficiency and heat dissipation efficiency of the chip, and fails to highlight the advantages of COB’s high stability and high image quality. At present, formal COB has reached the ceiling in terms of current chips and dot pitch, and has lost its competitiveness in the face of future demands for smaller chips (Micro LED) and smaller pitches (below P0.6).

2. Mixed COB

Mixed COB, that is, the three RGB chips are packaged on the PCB in the form of mixed positive and flip chips. For example, the common “two inverted and one positive” is a combination of one positive red chip and two flipped blue and green chips.

Popular Science This article will help you understand the difference between COB and full flip-chipThis solution was born around 2020. At that time, the price of flip-chip red light chips was high, so in order to balance cost and performance, the mixed solution came into being. However, this transitional solution has gradually faded out of history as the cost of flip-chip red light chips has fallen in recent years.1

3. Full Flip Chip COB

Full flip-chip COB, that is, the three RGB chips are all packaged on the PCB using flip-chip.

The electrodes of the flip chip can be directly bonded to the solder joints on the PCB board, so there is no need for solder wires, fewer solder joints, and higher stability. The GAP spacing of the chip solder pins is larger than that of the regular chip, which reduces the probability of electron migration, resulting in fewer dead lights and caterpillar problems, and longer module life. In addition, the flip chip has no electrodes and solder wires blocking the front, so the luminous area is larger, the luminous efficiency is higher, and the display effect is better. In the future, it will be the only one of the three solutions that can achieve smaller chips, smaller dot pitch, and enter the Micro LED technology path.